Ultrasensitive inductive debris sensor with a two-stage auto asymmetry compensation circuit

Min Qian,Yijun Ren,Guofeng Zhao,Zhihua Feng.

Link: https://ieeexplore.ieee.org/abstract/document/9177329

DIO: 10.1109/TIE.2020.3018066

Abstract

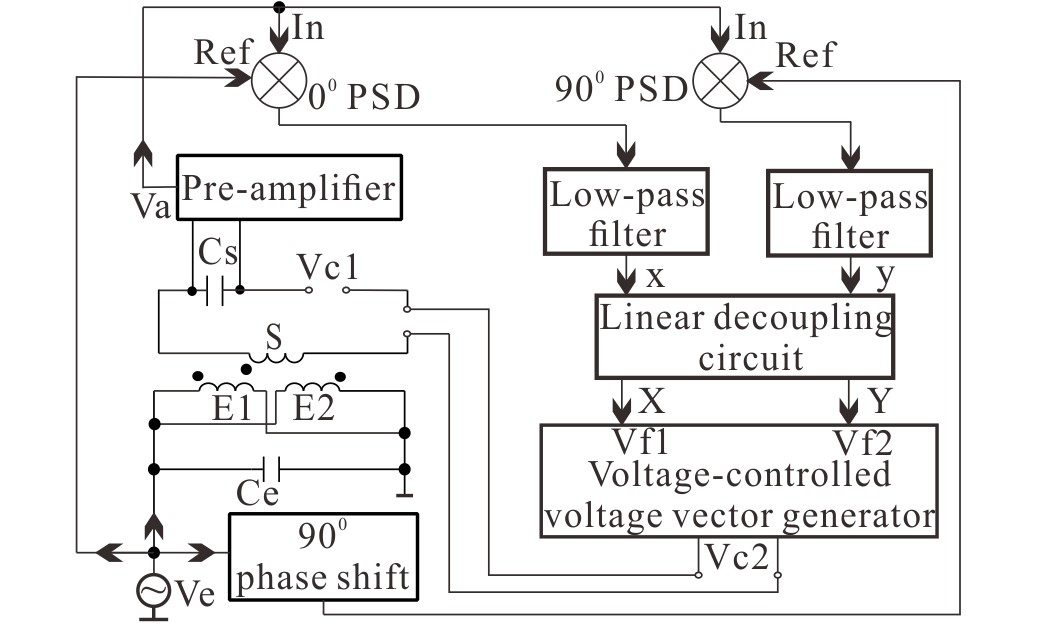

Inductive oil debris sensors have been widely used in the health monitoring of mechanical equipment. Such sensors are important for fault diagnosis, life prediction, and prevention of catastrophic failures. In this study, the concept that the residual voltage caused by the asymmetry of two incentive coils hinders the improvement of the sensor resolution is theoretically demonstrated for the first time. In order to achieve ultrasensitive detection, a novel two-stage auto asymmetrical compensation circuit (AACC) is introduced into the triple-coil debris sensor to automatically suppress the residual voltage in real-time. Experimental results show the successful detection of 70 μm (diameter or D) ferrous particles, 165 μm (D) nonferrous particles in a sensing channel with a diameter of 43 mm. The AACC is verified effective to maintain the residual voltage at an ultra-small value even in the presence of environmental fluctuations, and the sensitivity of the sensor using AACC is more than 31 times that of the sensor without AACC.

摘要

感应式油路磨粒传感器已广泛应用于机械设备的健康监测,在故障诊断、寿命预测以及预防灾难性故障等有着重要作用。本文首次从理论上证明了由两个激励线圈的不对称性引起的残留电压会阻碍传感器分辨率的提高。针对这一问题,我们在三线圈式磨粒传感器中引入了两级自动不平衡补偿电路(AACC)以自动、实时地抑制残留电压。实验结果表明,在内径43 mm的传感通道中成功检测到直径70μm的铁磁颗粒和直径165μm的非铁磁颗粒,使用AACC的传感器的灵敏度是不使用ACC的传感器的灵敏度的31倍以上;并且即使在环境波动的情况下,AACC仍可将残留电压保持在极小的值,最大程度地提高分辨率极限。

图1 自动不平衡补偿电路(AACC)反馈环控制示意图

图2 传感器有/无AACC时的残余电压随温度漂移情况对比

亮点:

首次理论证实残余电压限制传感器分辨率的提高;

使用与激励信号同源的补偿信号来抵消残余电压,降低激励源噪声的影响;

压控电压矢量发生器使用可变电容二极管进行自动平衡,电路简洁且高效;

线性解耦电路精确解耦残余电压幅度和相位信息并进行实时跟踪,使得AACC能自动、实时补偿缓变的残余电压,抑制环境干扰影响;

相比无AACC的传感器,有AACC的传感器灵敏度水平提高了31倍多,且AACC方案对多种精密探测场合有广泛的适用性。