Interference reducing by low voltage excitation for a debris sensor with triple-coil structure

Min Qian, Yijun Ren, Zhihua Feng.

Link: https://iopscience.iop.org/article/10.1088/1361-6501/ab49c5/meta

Abstract

Dielectric impurities, such as air bubbles and water droplets, which flow along lubrication systems can severely interfere with the performance of inductive debris sensors due to coil parasitic capacitances. This study proposes a novel triple-coil debris sensor with low voltage excitation to reduce the influence of variations in coil parasitic parameters and to improve the resistance to interference of dielectric impurities without sacrificing sensitivity to metallic particles. The sensor utilizes a 3-turn excitation coil made of Litz wire and two identical 60-turn sensing coils made of enameled wire. A sensor prototype with a compact and efficient signal processing system is constructed and several experiments are conducted to test its performance. Results show that the sensor can successfully detect 300 μm (diameter or D) high-carbon steel particles, 558 μm (D) copper particles, and 491 μm (D) aluminum particles in an oil pipe with an outer diameter of 50 mm. Comparative experiments indicate that for the sensor with conventional excitation method, the amplitude of the interference induced by an 8.5 mm (D) water droplet is equivalent to that of the interference induced by a 524 μm (D) ferrous particle, and a 10 mm (D) air bubble may be mistaken as a 557 μm (D) ferrous particle. No interference occurs under the same conditions for the sensor with low voltage excitation.

摘要

由于线圈寄生电容的影响,在润滑系统中流动的介电杂质,如气泡、水滴等,会严重干扰感应式磨粒传感器的性能。本文提出了一种具有低压激励方式的新型三线圈式磨粒传感器,以减少线圈寄生参数变化的影响,它能够在不牺牲对金属颗粒探测灵敏度的情况下,提高抗介质杂质干扰能力。该传感器采用了一个利兹线制成的3匝激励线圈和两个漆包线制成的60匝感应线圈,并构建了简洁、高效的信号处理系统。实验测试样机性能,发现该传感器可以在外径为50 mm的油管中成功检测到直径为300μm的高碳钢颗粒、558μm的铜颗粒和491μm的铝颗粒。对比实验结果表明,对于采用传统激励方法的传感器,直径8.5mm的水滴引起的干扰信号幅值等于直径524μm的铁磁性颗粒引起的干扰信号幅值,即直径8.5mm的水滴会被误认为直径524μm的铁磁性颗粒,同理,直径10mm的气泡等效于直径557μm的铁磁性颗粒,将会造成误判;而对于采用低压激励方法的传感器,在同等条件下不会产生干扰信号。

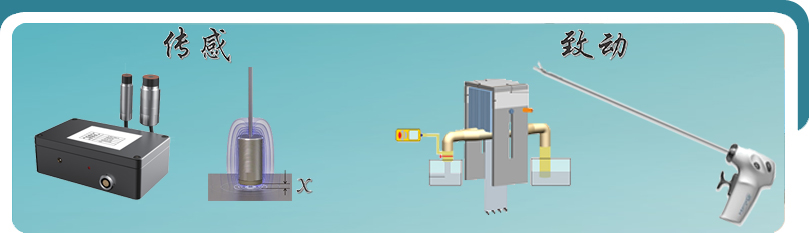

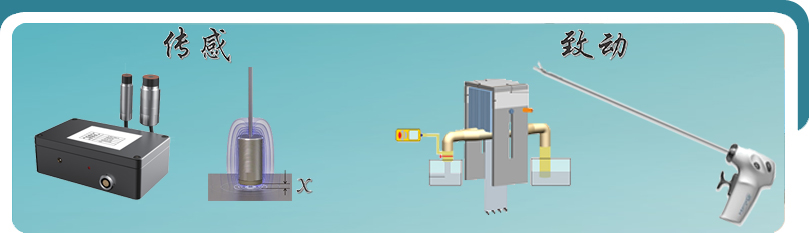

图1 探头结构示意图

图2 当不同直径的水滴通过管道时,采用传统激励方法的传感器的输出信号:(a)4 mm,(b)6.5 mm,(c)8.5 mm,(d)10 mm;采用低压激励方法的传感器的输出信号:(e)4 mm,(f)6.5mm,(g)8.5mm和(h)10mm

图3 当不同直径的气泡通过管道时,采用传统激励方法的传感器的输出信号:(a)4 mm,(b)6.5 mm,(c)8.5 mm,(d)10 mm;采用低压激励方法的传感器的输出信号:(e)4 mm,(f)6.5mm,(g)8.5mm和(h)10mm

亮点:

低压激励方法能够有效提高感应式磨粒传感器的抗介电杂质干扰能力,同时不牺牲其对金属磨粒的探测灵敏度;

制作的传感器样机能够成功消除由直径8.5 mm的水滴或直径10 mm的气泡引起的干扰信号;

该传感器能够在外径为50 mm的油管中成功检测到直径为300μm的高碳钢颗粒、 558μm的铜颗粒和491μm的铝颗粒。