DOI: 10.1063/5.0044522

ABSTRACT

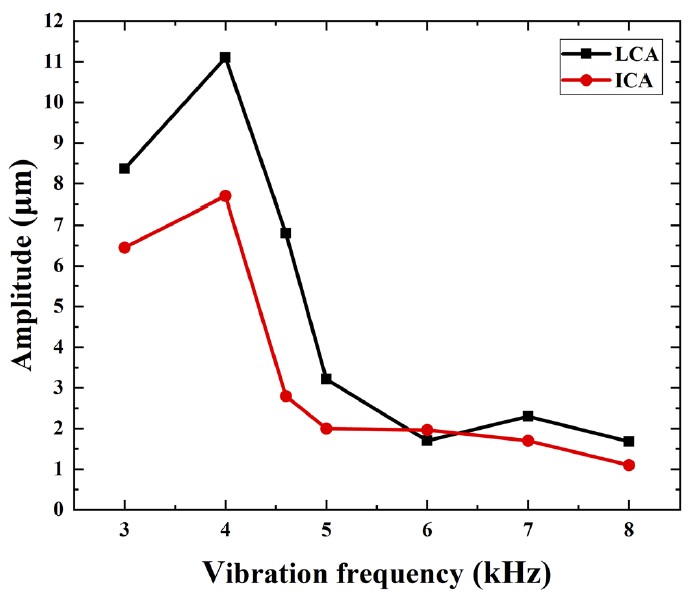

The high-frequency eddy current loss limits the output speed of the giant magnetostrictive actuator (GMA). This paper investigates a GMA using a laminated silicon steel core. Compared with the integral silicon steel core, the laminated silicon steel core can reduce the equivalent conductivity and eddy currents. The laminated structure reduces the magnetic reluctance of the core and increases the magnetic field intensity in the giant magnetostrictive material rod. Therefore, the actuator can output large vibration amplitude under high-frequency magnetic field. At the sinusoidal excitation current of 35A (rms) @ 2 kHz, the output vibration amplitude of the actuator using the laminated silicon steel core is 11.1 μm @ 4 kHz, which is 44.2% higher than that of the actuator with the integral silicon steel core. This indicates that the laminated structure of the magnetic core is beneficial to improve the output speed of GMA.

摘要

高频涡流损耗限制了超磁致伸缩执行器(GMA)的输出速度本文研究了使用叠片硅钢磁芯的GMA。与整体结构的硅钢磁芯相比,叠片硅钢结构可降低磁芯的等效电导率和涡流。叠片结构降低了磁芯的磁阻,增加了超磁致伸缩棒中的磁场强度。因此,致动器可以在高频磁场下输出较大的振动幅度。在35A(rms)@2kHz正弦激励电流下,采用叠片硅钢磁芯的致动器输出振幅为11.1μm@4 kHz,比采用整体硅钢磁芯的致动器高出44.2%.这说明磁芯的叠层结构有利于提高GMA的输出速度。

图片摘要

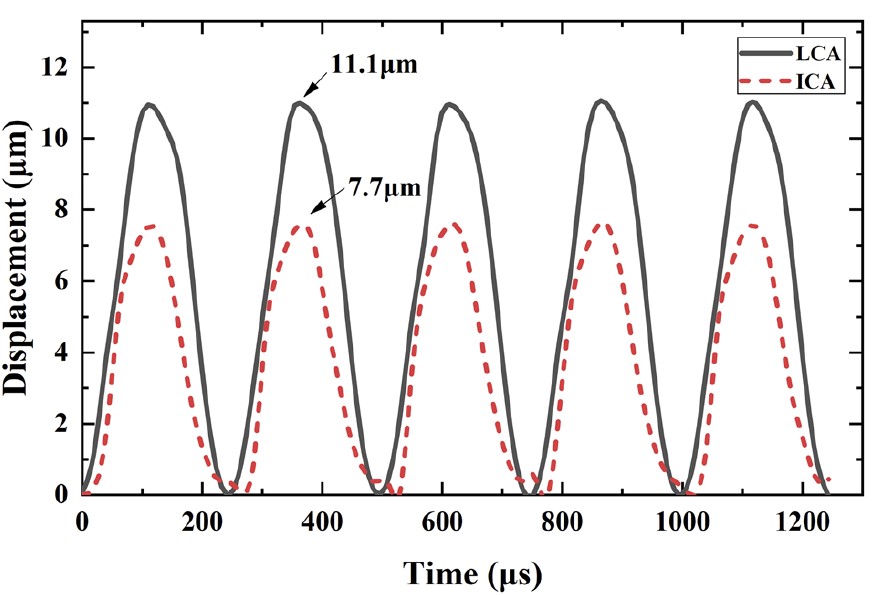

图1是将有效值为35A(rms),频率为2kHz正弦激励电流施加到激励线圈上,分别测量叠片磁芯致动器(LCA)与整体磁芯致动器(ICA)输出振幅。将致动器输出的位移沿时间轴展开,绘制得到的振动波形近似为正弦波。整体磁芯致动器的振动幅度为7.7μm,而叠片磁芯致动器的振幅为11.1μm。叠片磁芯致动器的输出速度比整体磁芯致动器高44.2%。实验结果表明,叠片磁芯致动器的高速特性优于整体磁芯致动器。这验证了叠片结构的磁芯有利于降低磁路元件的涡流损耗。

FIG.1 Vibration waveform of the actuator under the excitation current of 35 A(rms) @ 2 kHz.

图2表明,当振动频率小于5kHz时,叠片硅钢磁芯致动器(LCA)的振动幅度大于整体硅钢磁芯致动器(ICA)的幅度;当振动频率大于5kHz时,两者的振幅都较小。

FIG.2 Amplitude–frequency characteristic curve of actuator vibration.

亮点

将E型变压器的叠片硅钢式磁芯作为磁致伸缩致动器的磁芯,并利用利兹线绕制励磁线圈,降低了磁致伸缩致动器的涡流损耗,提升了其高频输出速度。

少匝数的励磁线圈的电感值仅为μH级别,在激励电压和安匝数一定的情况下,提升了致动器的快速致动能力。