Link:https://doi.org/10.1063/5.0090624

DOI:10.1063/5.0090624

Abstrcat

The quality factor (Q factor) is one of the most important parameters for a resonant sensor since it determines the performance of the resonant system. The mass distribution imbalance caused by the fabrication error has a great impact on the anchor loss, and the Q factor will, thus, decrease drastically. In this work, a vibration isolation structure of the tuning fork is proposed to eliminate the influence of weight imbalance so that an ultra-high Q factor can be obtained. With this designed vibration isolation structure, we prove that the anchor loss can be reduced significantly via numerical simulations, and we experimentally demonstrate that increases by at least 78.6%. Moreover, the surface loss of the fused quartz tuning fork is also reduced after chemical etching, and we use interdigital electrodes for electrostatic excitation to avoid loss caused by the metal film employed in the conventional excitation method. Finally, the Q factor increases to 3×106, which is one of the highest test values known at present, and it is 127% larger than that of the tuning fork that uses a coated metal film for electrostatic excitation.

文章摘要

质量因数(Q factor)是谐振式传感器最重要的参数之一,因为它决定谐振系统的性能。由制造误差引起的质量分布不平衡对锚固损失有很大影响,因此Q值将显著降低。在这项工作中,提出了音叉的隔振结构,以消除重量不平衡的影响,从而可以获得超高的Q值。采用这种设计的隔振结构我们通过数值模拟证明了锚固损失可以显著减少,我们通过实验证明,至少增加了78.6%。此外,化学蚀刻后,熔融石英音叉的表面损失也减少了,并且我们使用叉指电极进行静电激励,以避免由传统激励方法中使用的金属薄膜引起的损失。最后,Q因子增加到3×106,这是目前已知的最高测试值之一,它比使用涂层金属薄膜进行静电激励的音叉大127%。

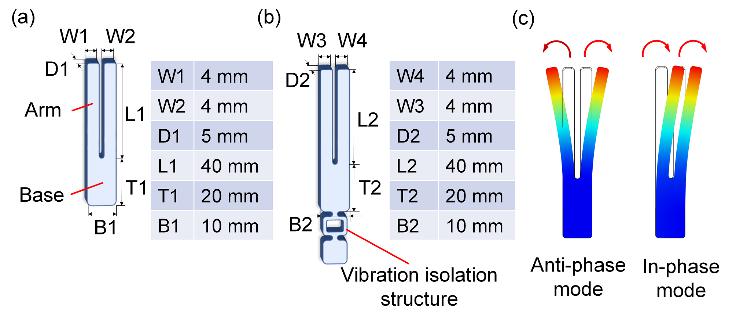

图1:普通结构音叉和非普通结构音叉

在普通结构音叉上增加一个隔振结构,以消除重量不平衡的影响。能够减少音叉振动时能量传导至底座上,从而提高Q值。后面是音叉振动的同相和反相模态。

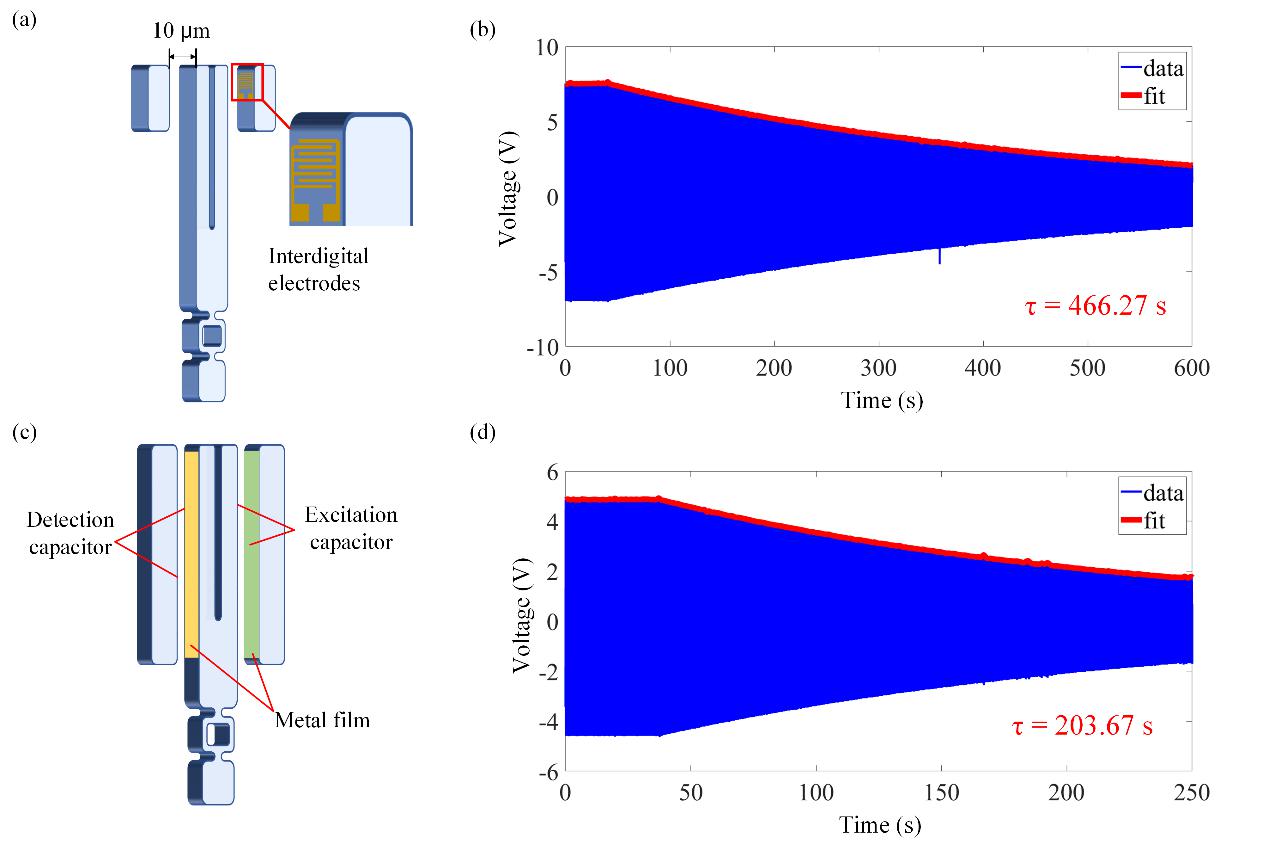

图2: 带有隔振结构音叉的Q值测试示意图

图片显示了两种激励和检测振动的方法,使用叉指电极,能够实现非接触激励和检测。相比于传统的利用导电金属薄膜实现静电激励和检测振动,能够避免金属消耗能量,从而得到更高的Q值。

亮点:

设计出具有隔振结构的音叉,以消除重量不平衡的影响,从而可以获得超高的Q值。

提出了一种新的激励和检测振动的方法。使用叉指电极进行静电激励,以避免由传统激励方法中使用的金属薄膜引起的损失。

是目前已知的Q值最高的音叉之一。