DOI: https://doi.org/10.1016/j.cja.2023.06.024

Abstract

Traditional single-acting piezoelectric-hydraulic hybrid actuators usually have the problem of inertial force caused by flow pulsation of the liquid, which degrades their output performance. To suppress or solve the associated inertial force and enhance its output capabilities, this paper starts from the liquid supply source and proposes a new type of double-acting piezoelectric-hydraulic hybrid actuator with four check valves acting as mechanical diodes.The composition structure and working principle of the new hybrid actuator have been introduced in detail. The actuator was fabricated, its output performance was studied experimentally, and the influence of excitation voltage, frequency and bias pressure on it were tested. When the excitation voltage is 700 Vp-p and the bias pressure is 2 MPa, the pulsation ratesof the new hybrid actuator at 400 Hz, 500 Hz and 600 Hz are 2.29, 2.08 and 1.78, respectively, while of the single-acting hybrid actuator under the same conditions are 10.98, 11.05 and 17.12. Therefore, the liquid pulsation rate of the new hybrid actuator is significantly reduced, which is beneficial for improving the flow uniformity and weakening the influence of inertial force on the hybrid actuator. This strategy ultimately leads to a maximum no-load velocity of 168.1 mm/s at 600 Hz and a maximum blocking force of 141 N at 450 Hz for the new hybrid actuator. The geometric size of the new hybrid actuator is increased by 16.3% compared to the original prototype. In addition, this strategy has the potential to be used in other electrohydrostatic actuators to improve their performance.

文章摘要

传统的单作用压电液压混合致动器通常存在液体流量脉动引起的惯性力问题,从而降低其输出性能。为了抑制或解决相关的惯性力并提高其输出性能,本文从液体供应源出发,提出了一种新型双作用压电液压混合执行器,该执行器具有四个作为机械二极管的止回阀。新型混合执行器的组成结构和工作原理被详细介绍了。致动器被制作了,对其输出性能进行了实验研究,也测试了激励电压、频率和偏压对它的影响。当激励电压为700 Vp-p,偏置压力为2 MPa时,新型混合执行器在400 Hz、500 Hz和600 Hz下的脉动率分别为2.29、2.08和1.78,而相同条件下单作用混合执行器的脉动率分别为10.98、11.05和17.12。因此,新型混合执行器的液体脉动率得到了显着降低,这有利于提高流动均匀性、减弱惯性力对混合执行器的影响。该策略最终使新型混合致动器在600 Hz时的最大空载速度为168.1 mm/s,在450 Hz时的最大阻挡力为141 N。在几何尺寸上,新型混合执行器比原始样机增加了16.3%。 此外,该策略也具有应用于其他电动静液致动器以提高其性能的潜能。

图片摘要

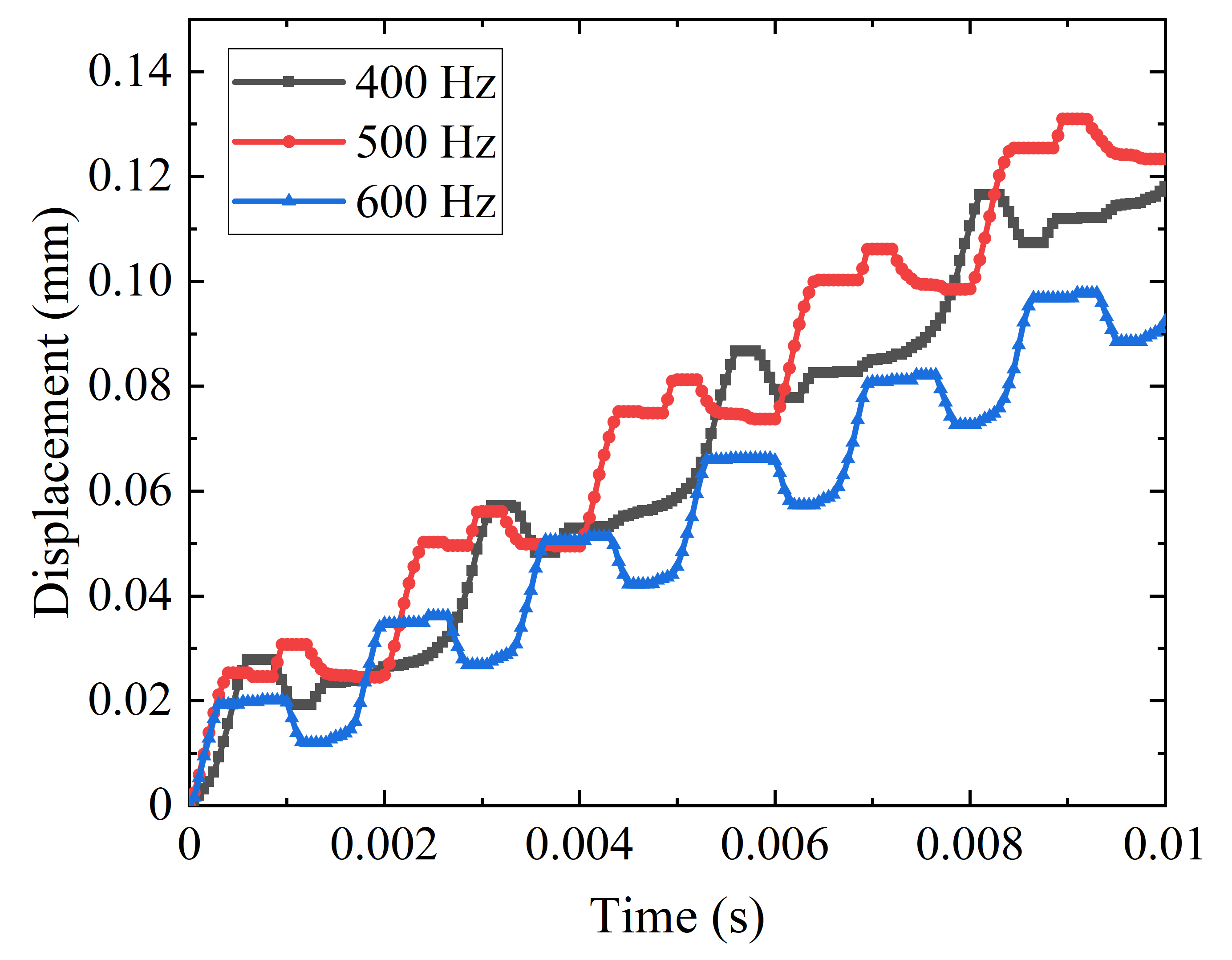

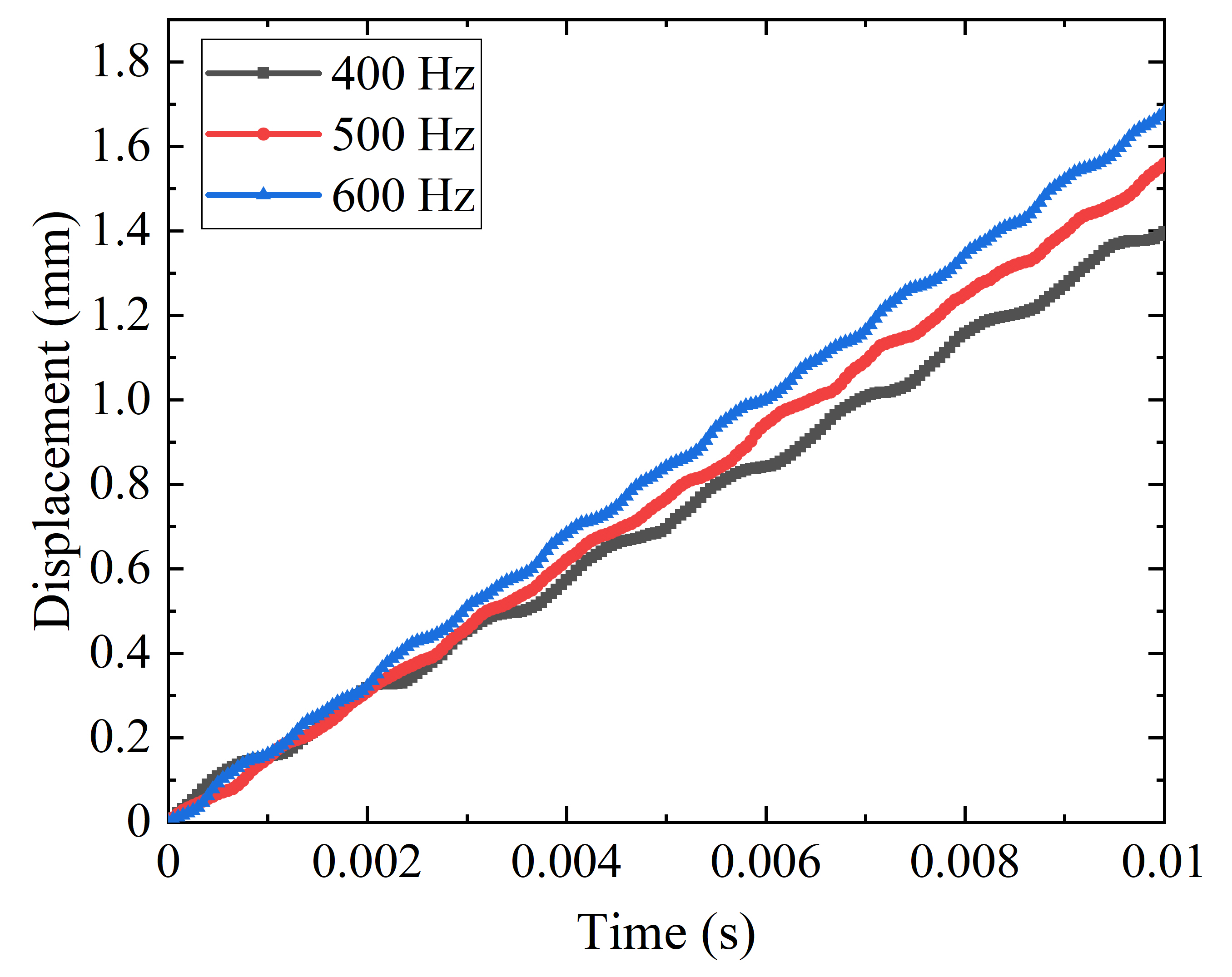

传统的单作用混合致动器的输出位移由于液体排放的不连续性而表现出motion-stop特性。 这将导致流量脉动,进而导致惯性力对输出性能产生重大影响。另外,液压杆在运动过程中存在反向位移,这可能是由于阀门密封不充分造成的。反向位移会加剧液体的流动脉动,增大惯性力对压电器件的影响,进一步降低其输出性能。与上述情况不同,双作用混合致动器的输出位移没有出现反向位移,并且输出位移的均匀性得到了比较显著的提高。另外,对于400 Hz、500 Hz和600 Hz三种不同的激励频率来说,当激励频率较高时,双作用混合致动器的输出位移较大,脉动率较低,这是由于压电叠堆的高功率密度特性以及对相关惯性质量的抑制导致的。而由于相关惯性力等问题,单作用混合执行器不会表现出这种趋势。

(a) (b)

Fig. 1. The movement of the hydraulic rod within 0.01 s under excitation conditions of voltage of 700 Vp-p and a bias pressure of 2 MPa. (a) For the single-acting hybrid actuator. (b) For the double-acting hybrid actuator.

亮点:

1.针对目前压电液压驱动系统中普遍存在的问题,我们首次从供液源的角度来抑制系统的流量脉动。 实验结果表明,该方法能够有效降低相关惯性力的影响,显着提高执行器的输出能力。

2.在激励电压700 Vp-p、偏置电压2 MPa、频率600 Hz下,新型混合执行器可输出最大速度168.1 mm/s; 执行器的最大阻挡力为141 N,是在激励频率为450 Hz时获得的。 新型混合执行器的输出性能较为优异,具有应用于旋翼机、工业机器人、航空航天等领域的潜力。

3.新型混合执行机构在不改变阀门相关参数及其密封性的情况下,可以防止液压杆反向位移,降低了对阀门的要求,节省了制造成本,为需要避免液压致动器反向位移的用户提供了新的选择。

4.所提出的策略对其他电动静压执行器提高其输出性能具有借鉴意义。